What is Flexible PCB (FCBs)? Distinctions between FCBs and rigid PCBs and the benefits of FCBs.

1. What is a Flexible PCB

Flexible Printed Circuit Boards (FCBs) are application products of flexible plastic materials such as polyimide, polyester, or PEEK (Polyether Ether Ketone). Manufacturers commonly use them in electronic devices where space is a critical factor, such as mobile phones, wearable devices, cameras, and medical equipment. Flexible PCBs can be designed to fit into tight spaces and can be shaped to fit into unique form factors, making them a versatile option for many applications. They are also durable and resistant to vibration and shock.

2. What are the differences between FPCs and rigid PCBs?

2.1 Material

FPCs are made of flexible plastic materials, allowing them to bend, twist, and fold to fit into tight spaces. Rigid PCBs, on the other hand, are made of rigid materials, like fiberglass, and cannot bend or flex.

2.2 Solder mask

Solder mask is a layer of polymer that is applied to the surface of a printed circuit board (PCB) to protect the copper traces on the board from oxidation, contamination, and other forms of damage. Typically, FPCs have a thin polyimide surface layer that can be drilled through or laser-cut to gain access to the internal parts.

2.3 Price

Flexible printed circuit boards (FPCs) generally tend to be more expensive than rigid PCBs due to the added cost of the flexible materials used in their construction. The specialized manufacturing processes for FPCs also tend to be more complex than traditional rigid PCB manufacturing, which can also increase the cost. Additionally, FPCs often require more complex assembly techniques, such as the use of specialized connectors or surface mounted components, which can add to the overall cost. However, the cost of FPCs can vary depending on the specific design requirements and complexity of the board.

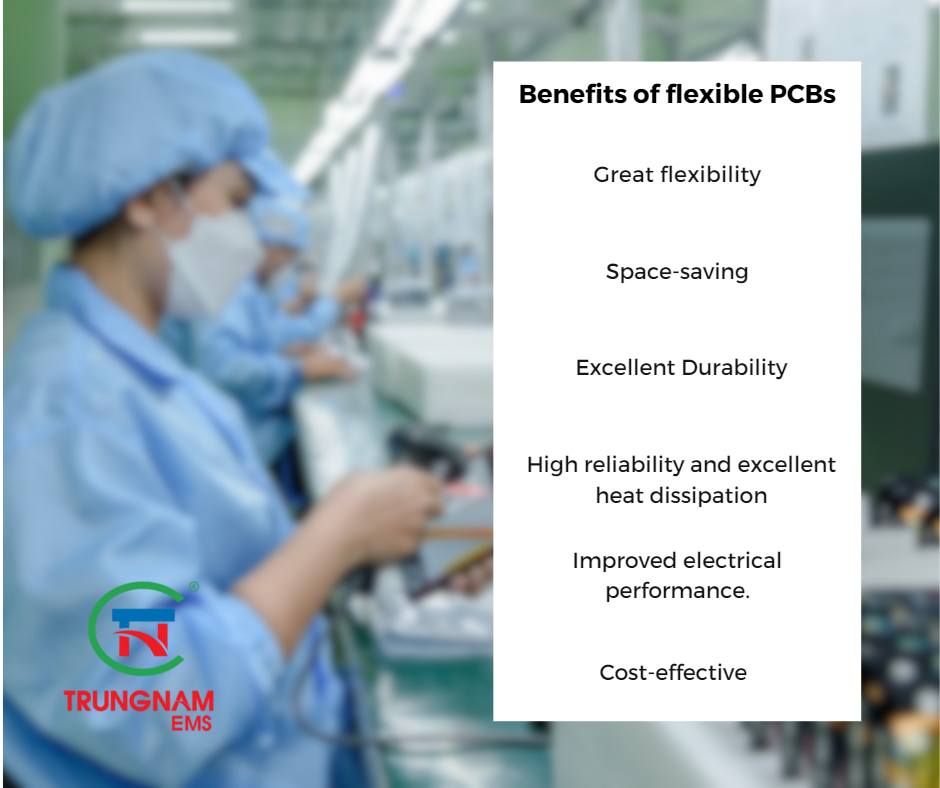

3. Benefits Of Flexible PCB (FCBs)

3.1 Great flexibility

As the name suggests, flexible PCBs are flexible and we can be bend or fold them to fit into tight spaces or irregular shapes, which is not possible with rigid PCBs.

3.2 Space-saving

Flexible PCBs are thinner and lighter than rigid PCBs, which makes them ideal for applications even in limited space .

3.3 Excellent Durability

Flexible PCBs are less prone to damage from vibrations, shock, and thermal cycling compared to rigid PCBs.

3.4 High reliability and excellent heat dissipation

FPC applications don’t need mechanical connectors, which increases their longevity in severe situations. Additionally, FPCs have a superior capacity for heat dissipation than rigid PCBs.

3.5 Improved electrical performance.

Flexible PCBs have lower signal loss and crosstalk compared to rigid PCBs, making them ideal for high-speed and high-frequency applications.

With advancements in manufacturing technology, the cost of producing flexible PCBs has decreased, making them an affordable option for many applications.

3.6 Cost-effective

Conclusion

Overall, flexible PCBs offer a range of benefits over traditional rigid PCBs. Nowaday, people use FPCB in many fields, including consumer electronics, medical devices and automotive electronics. Especially, Trung Nam EMS used in more than 40 engineering fields to design and manufacture printed circuit boards that support the technology.