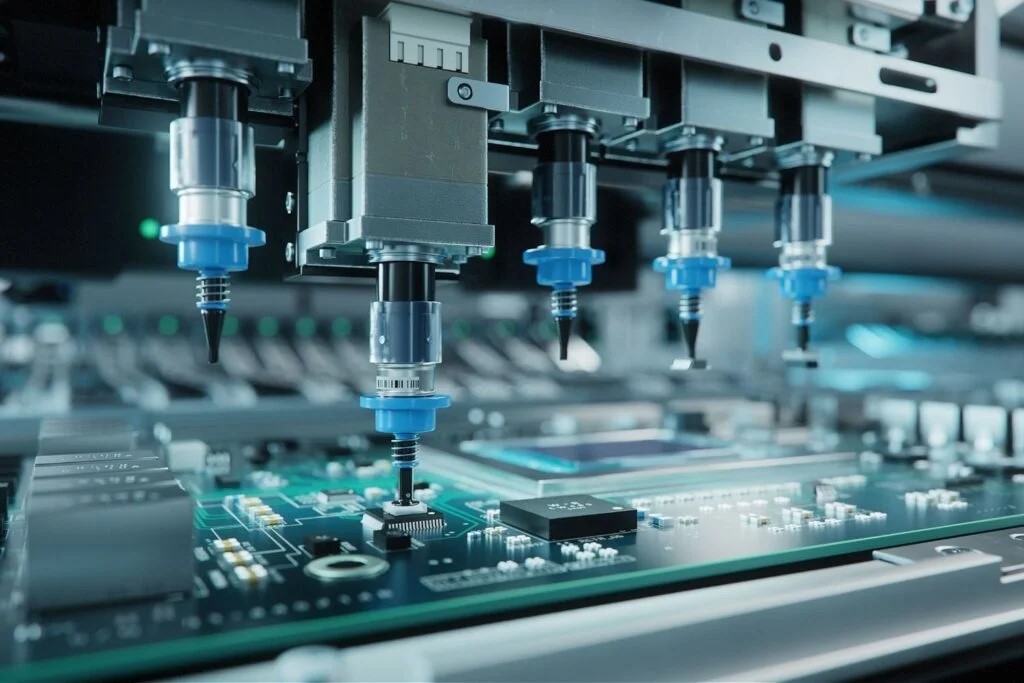

At first, Surface Mount Technology (SMT) is revolutionizing the electronics manufacturing services industry. This post explores the critical aspects of SMT, including its benefits, production processes, and real-world applications, particularly highlighting the success of Trung Nam EMS (TNEMS) in Vietnam.

The Importance of SMT Technology in Electronics Manufacturing Services

Nowaday, SMT is widely adopted in the electronics industry due to its numerous advantages:

-

- Optimized Product Design: SMT components are small and compact, making them ideal for modern electronic devices, helping to save space and meet the trend of miniaturizing designs.

- High Reliability: SMT solder joints are durable, capable of withstanding harsh environmental conditions and ensuring stable product performance.

- Increased Productivity and Efficiency: The automation of the SMT process reduces human errors, shortens production cycles, and improves cost-efficiency.

- Environmental Benefits: SMT helps minimize material waste and energy consumption, contributing to sustainable production practices.

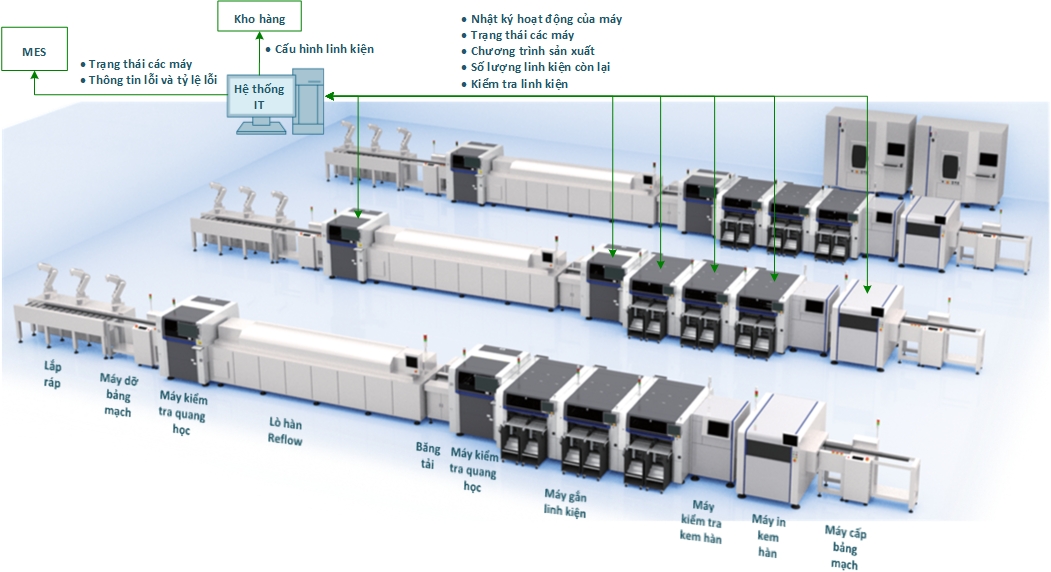

Structure of a Typical SMT Production Line

Basically, an SMT production line integrates various automated systems and key machines to carry out the different stages of the manufacturing process. A typical SMT line consists of the following main components:

-

- PCB Loader: The loader automatically feeds the PCB into the production line, ensuring a continuous and accurate workflow. This equipment also minimizes downtime and manual labor.

- Stencil Printer: The stencil printer applies a thin layer of solder paste onto the PCB pads where components will be placed, ensuring precise soldering.

- Solder Paste Inspection (SPI): SPI machines use optical technology (2D or 3D) to check the thickness, volume, and placement of the solder paste to ensure quality.

- Component Mounter: This machine places the electronic components onto the PCB at predefined positions with high precision. It uses flexible nozzles and camera systems to handle various component types.

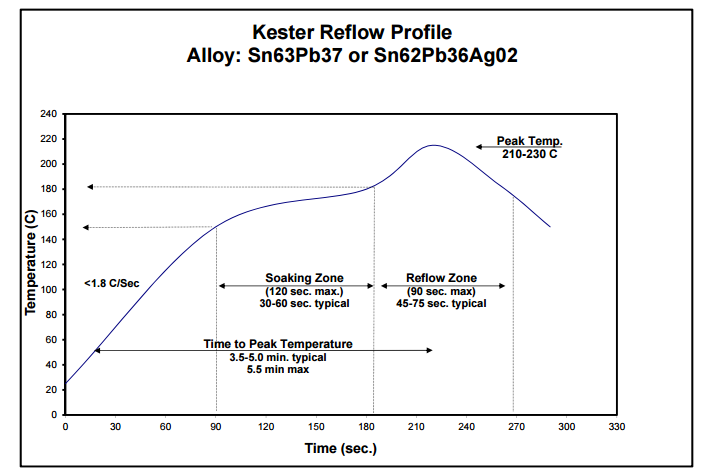

- Reflow Oven: The reflow oven melts the solder paste, securely attaching the components to the PCB. It follows a strict temperature profile to ensure quality solder joints without damaging components.

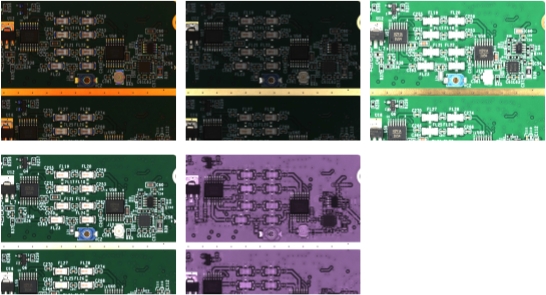

- Automated Optical Inspection (AOI): AOI machines are used to detect placement errors or soldering issues, such as misalignment, missing components, or faulty solder joints. These checks occur both after component placement and after the reflow soldering process.

- Unloader: The unloader automatically removes completed or partially completed PCBs from the line, reducing manual handling and maintaining a continuous production flow.

The SMT Production Process in Electronics Manufacturing

The SMT production process consists of several key steps, each critical for ensuring a successful assembly:

-

- Data Preparation: This step includes generating BOM (Bill of Materials), CAD data, and machine programming to optimize the design for SMT.

- Material and Component Preparation: Components are inspected and prepared for assembly, ensuring quality and readiness.

- Automatic PCB Feeding: The PCB is automatically fed into the production line by the loader, starting the process.

- Solder Paste Application: The stencil printer applies solder paste onto the PCB pads.

- Solder Paste Quality Check: SPI machines inspect the solder paste quality to ensure adherence to specifications.

- Component Placement: The mounter places the components onto the PCB.

- Component Inspection: AOI systems check component placement for accuracy.

- Reflow Soldering: The PCB passes through the reflow oven, where heat melts the solder paste, securely attaching the components to the PCB.

- Post-Soldering Inspection: AOI checks the soldering quality to identify any issues such as excess, insufficient solder or short circuits.

- Manual and X-ray Inspection: If needed, manual inspection and X-ray machines help detect hard-to-spot defects, such as those under BGA (Ball Grid Array) components.

- Final Testing: Completed products undergo final quality checks to ensure functionality and aesthetics before packaging.

The Role of IT and MES in SMT Production

In fact, advanced IT systems and Manufacturing Execution Systems (MES) are crucial for managing and optimizing the SMT production line. The IT system monitors and connects production equipment, inventory, and MES, ensuring smooth operation and real-time data flow across the factory. Here’s how these systems enhance the SMT process:

- IT Systems: They manage machine operations, track component inventory, and connect with MES for real-time production monitoring.

- MES: The MES system handles scheduling, traceability, performance analysis, and quality control, ensuring that all production stages are optimized and aligned with customer requirements.

Case Study: Trung Nam Electronics Manufacture Services (TNEMS)

Firstly, Trung Nam EMS (TNEMS) exemplifies the successful implementation of SMT technology in a modern manufacturing environment. TNEMS operates a cutting-edge SMT production line equipped with advanced Yamaha mounters, reflow ovens, and AOI systems, all integrated into a robust IT and MES framework. This integration optimizes production for high-quality output and efficient resource use. The company has notably succeeded in the electronics manufacturing sector, producing high-quality PCBs for local clients such as EVN and Datbike. In addition, it has expanded its reach by exporting products like JBL speaker circuits and automotive seat temperature control boards to Europe and the United States. Secondly, TNEMS is actively pursuing growth, with plans to open a new 10,000m² factory in Da Nang. This expansion will not only enhance production capacity but also facilitate the further integration of MES and R&D systems, thereby fostering innovation and improving operational efficiency.

In summary, SMT technology has revolutionized the electronics manufacturing industry, providing numerous benefits, including higher efficiency, better quality, and more sustainable practices. The integration of IT and MES systems is crucial in optimizing SMT production, enabling manufacturers to meet the demands of a rapidly evolving market.

The success of Trung Nam Electronics Manufacturing Services (TNEMS) serves as a clear example of how SMT technology, combined with advanced IT and MES systems, can drive innovation, improve quality, and position companies for success in the global electronics supply chain. With continuous improvements and ongoing expansion, TNEMS is not only establishing a strong foundation for becoming a leading player in the high-quality electronics manufacturing sector in Vietnam but is also positioning itself to compete on a global scale.

Keywords:

Trung Nam EMS (TNEMS)

Surface-Mount Technology (SMT)

Electronics manufacturing

SMT production line

PCB assembly

Manufacturing Execution System (MES)

IT systems in manufacturing

Automated Optical Inspection (AOI)

Reflow soldering

Electronics contract manufacturing

Read more detail on Tu Dong Hoa Ngay Nay

Trung Nam EMS Click Here