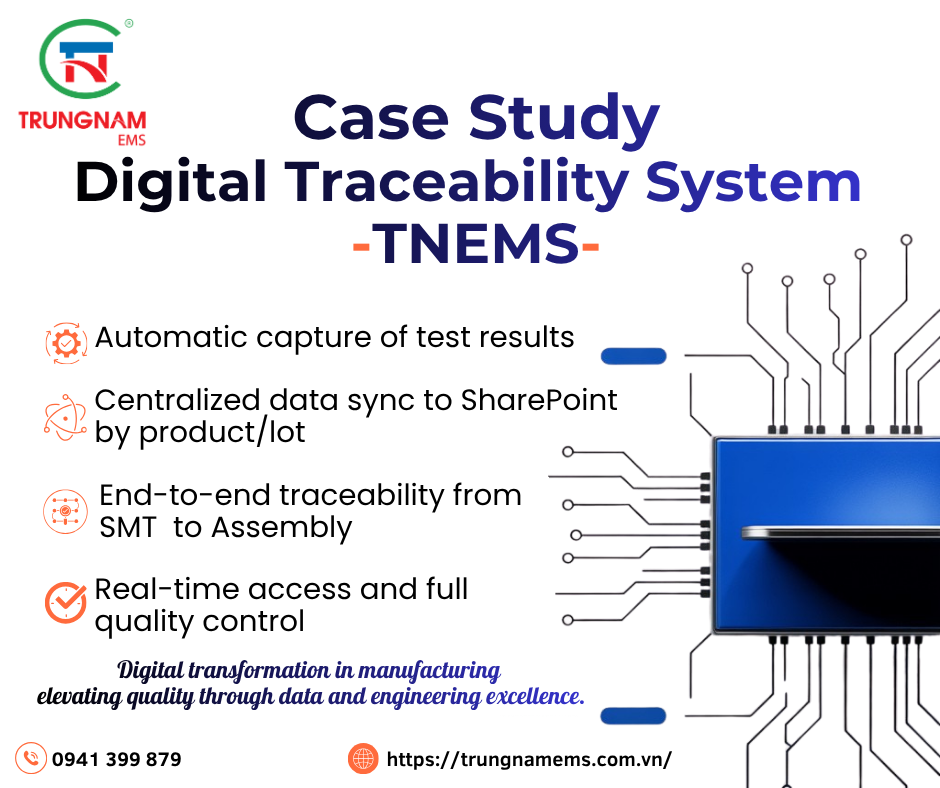

In the electronics manufacturing industry, achieving end-to-end production traceability is a critical requirement for quality assurance and customer confidence. At Trung Nam EMS, an EMS Vietnam (TNEMS), our engineering team identified a challenge: manual operations in the assembly process often led to missing steps, inconsistent process control, and limited visibility across production lines.

Therefore, to overcome these issues and meet customers’ growing expectations for complete traceability, TNEMS has successfully developed an in-house Digital Traceability System — integrating key MES (Manufacturing Execution System) functions to improve quality control, efficiency, and data transparency.

Solution: Digital Traceability System in EMS Vietnam

The TNEMS Digital Traceability System was designed and developed entirely by our in-house engineering team with extensive EMS Vietnam experience. The system provides seamless data capture, synchronization, and monitoring across production lines.

Key Features

• Automatic test result capture from equipment

• Data synced to SharePoint by product/lot with unique product IDs, ensuring end-to-end traceability from SMT to Assembly

• Instant access to complete data — from material input to finished goods shipment

• Full control of process and quality parameters

Through this solution, every product manufactured at TNEMS can be traced back to its source materials and process history — enabling transparency, accountability, and reliability.

Results & Value Delivered

By implementing the Digital Traceability, TNEMS has achieved measurable improvements across multiple areas of production. As a result, the factory now benefits from:

🎯 Key Benefits

- Faster response time to customer traceability requests

- Reduced manual errors and increased process consistency

- Improved data transparency for quality audits and production reviews

- Optimized operational efficiency and lower maintenance costs

Consequently, this innovation not only strengthens TNEMS’s manufacturing capabilities but also reinforces our long-term commitment to digital transformation and Industry 4.0 excellence.

Next Step

Moving forward, TNEMS is now focusing on automating test data reporting for every shipment — further enhancing digital manufacturing through smarter data management and predictive analytics.

Conclusion

TNEMS’s commitment to engineering excellence, data-driven manufacturing, and quality-first production. By leveraging internal expertise, we have created a scalable, cost-efficient solution that empowers customers with full visibility into their production process.

✨ Digital transformation in manufacturing — elevating quality through data and innovation.

🚀 Looking for a reliable EMS partner with advanced traceability and quality management systems?

Contact TNEMS today to explore how our digital manufacturing solutions can bring transparency, speed, and quality to your production process.