About Us

About

Trung Nam EMS

Trungnam EMS Joint-Stock Company was a member of Trungnam Group. By unique combination of R&D and PCB Assembly, we support from design to production, from prototype to mass production with international quality in Vietnam for lower-cost.

Mission: Becoming One-stop-shop contract Electronics Manufacturing Services of tier-one quality, low cost services in any volumes and simple business process.

Our Quality Services Policy: Quality first, on-time delivery, excellent customer service, and cost-competitive. Execution is the key: Speed, accuracy and precision with flexibility make a win-win strategy for mutual growth.

MISSION

EMS Trung Nam affirms its ability to succeed in the electronic manufacturing services with the mission of bringing sustainable trust to shareholders based on effective operations, investment in modern, quality construction, contribute to the common prosperity of the home country on the way of world economic integration.

EQUIPMENT

Solder Paste Printer YCP10 by Yamaha

The YCP10 offers high-performance printing in a compact body that is also cost effective. It has the versatility to handle large circuit boards up to 510mm, as well as a wide variety of stencil sizes (750mm x 750mm) despite its compactness.The YCP10 comes standard with Yamaha Motor's unique 3S head*2 and stencil suction mechanism. The average printed time is 13.5 seconds. The YCP10 comes standard with many user-friendly features including a graphic alignment function to allow the circuit board and printing stencil to be aligned seemlessly, and a touch panel which allows all operations to be comfortably carried out as if working with a tablet computer.

Solder Paste Inspection YSI-SP by Yamaha

Achieves high-accuracy high-speed inspections using 3D+2D inspection.

Optional features to enable handling various products

Two Mounters YSM20R by Yamaha

World’s fastest mounting speed. Featuring a new wide-scan camera with improved component adaptability.

Improving line operating rate without stopping the machine.

Convection Reflow Ovens 1810 MK5 – Heller

The World’s Best SMT Reflow Oven. 10 Zone Reflow Oven with Static Pressure / Computer Fan Speed Control of Heater Module Blowers (Three Groups; Zones Top, Bottom & Reflow Zones)

5 Thermocouple “Real Time” profiling. Complete KIC & ECD Profiling & Storage Software.

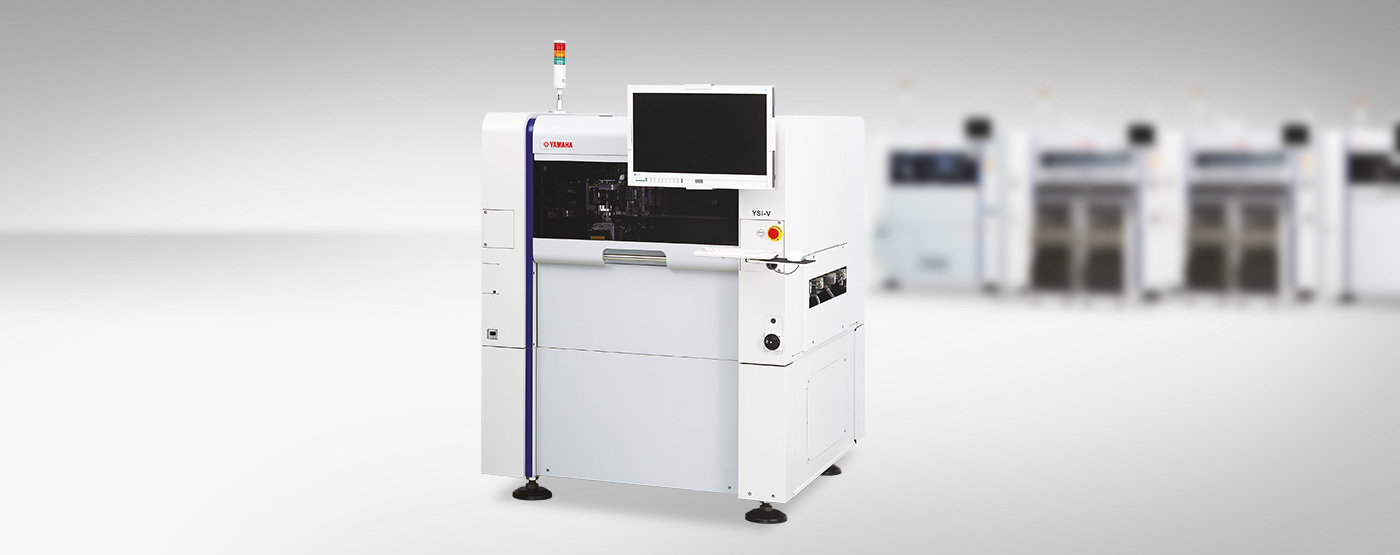

Automated Optical Inspection 3D YSI-V by Yamaha

Performs 2 Dimensional inspections, 3 Dimensional inspections, and 4-direction

It has more than double the inspection capability of ordinary inspection systems.

Wave Soldering Powerflow AIR H from Ersa

Regards as one of the most reliable High-performance wave soldering system with flexible solder bath technology

Consists of a Spray fluxer with intelligent spray pattern programming which can precisely yield consistent fluxing result

Selective Soldering ECO Selec 4 from Ersa

Modular selective platform for highly efficient and flexible inline soldering

The ECOSELECT 4 is Ersa’s newest selective soldering system. It is a compact system that is perfectly suited for small up to medium-sized batches where flexibility is essential

High performance micro focus X-Ray Inspection System μRay8000 by Matsusada

Real-time X-ray allows for intuitive navigation of complex printed circuit boards and electronic components to quickly trace defects. In automated inspection mode, samples can be inspected at the highest throughput.

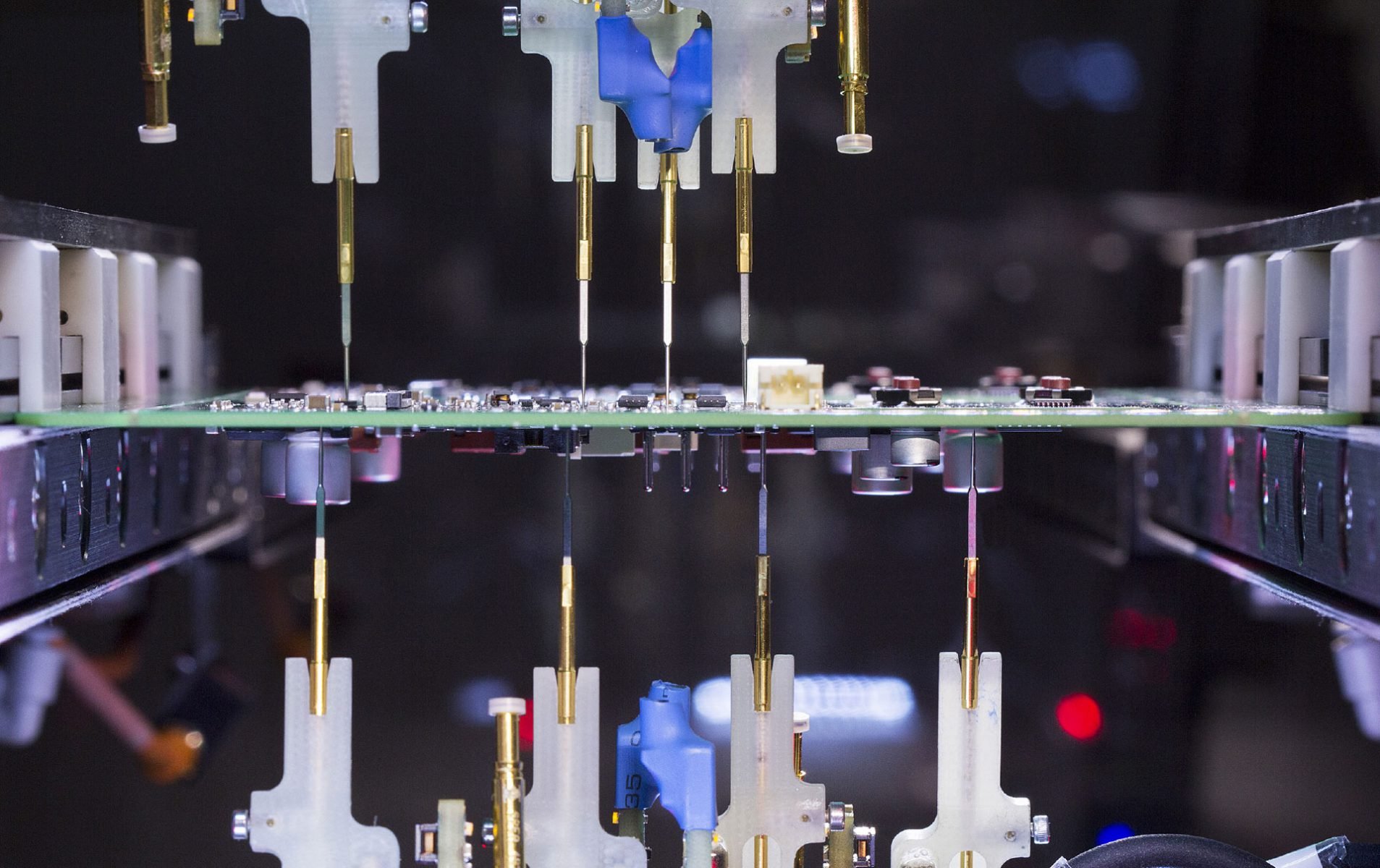

Flying Probe Testers

The flying probe test system uses 4 high speed independently moving probes, to detect manufacturing defects on printed circuit boards and eliminate the requirement for a conventional bed-of-nails fixture.

Stencil Cleaner SC-AH100E-LV by Sawa Ecobrid

Use Ultrasonic and suction drying system Simultaneous process of cleaning and drying can realize a high-speed cleaning.

Using Low VOC solvent can reduce organic solvent consumption that harms human health and environment.

PCB Separation AUO 3000 by Aurotek

The best PCB Separator to fit the mass production in SMT line

Dual working table enhances the production efficiency.

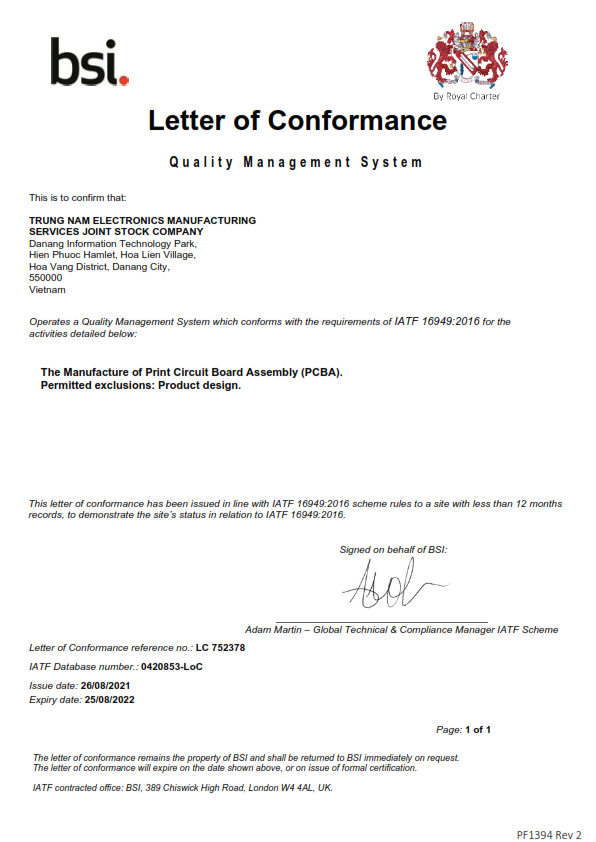

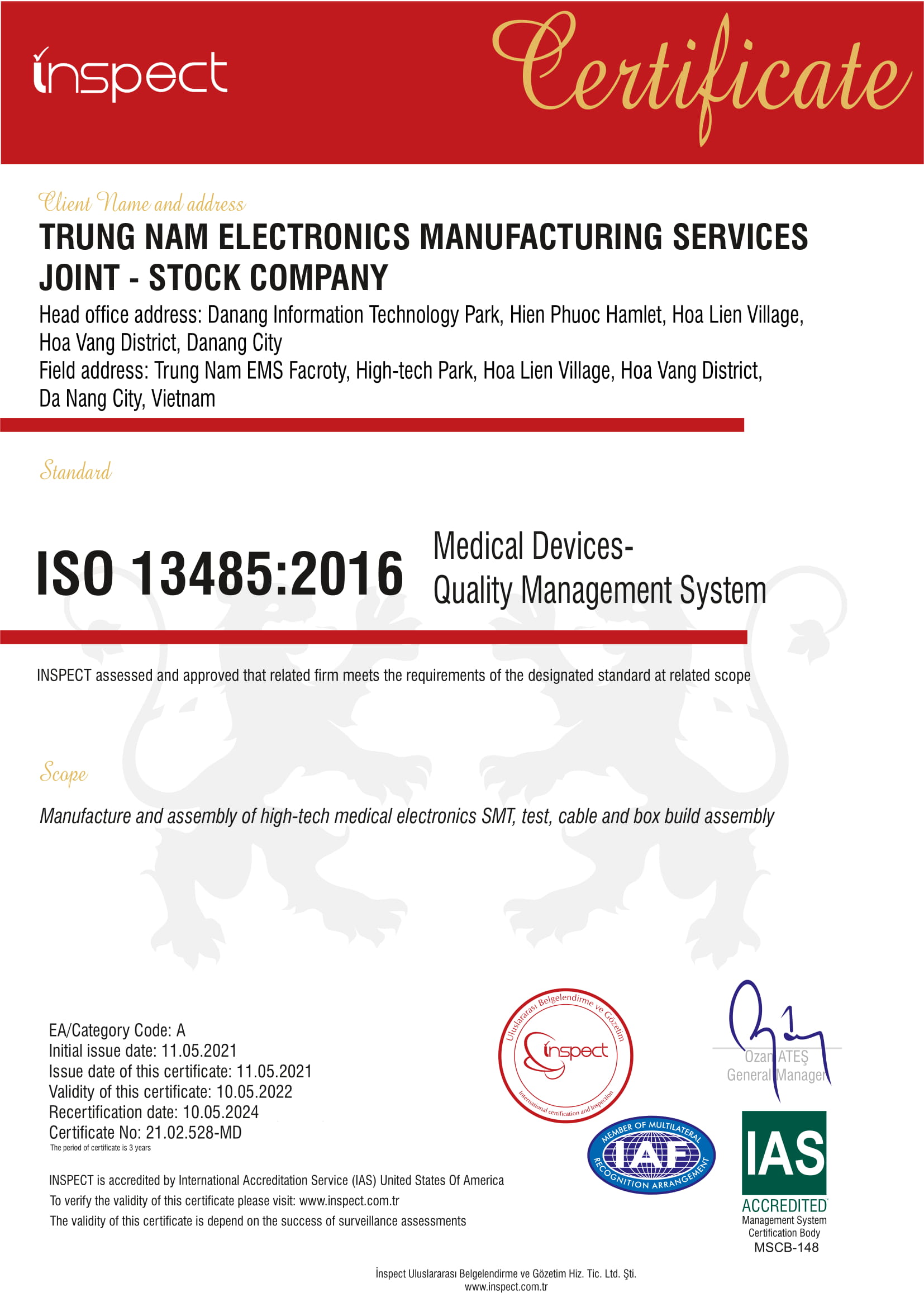

QUALITY SYSTEMS

Quality Policy: Exceed customer expectations while striving for excellence through dedication, empowerment and continuous improvement. Trung Nam EMS is committed to providing quality services that consistently meet legal and statutory requirements and exceed customers’ expectations for performance, value, quality and schedule. Trung Nam EMS’ Quality Management Process is based on its commitment to customer satisfaction, continuous improvement and the ongoing evaluation and improvement of its business processes at all levels within the company.

Trung Nam EMS strives to achieve continual improvement of its people, processes and services by certification to the requirements of ISO 9001:2015; ISO 14001:2015; ISO 13485:2016 and IATF 16949:2016; and by maintaining and continually improving the QMS effectiveness, through process control, supplier development and monitoring, effective communication, employee involvement and management commitment.

INTRODUCTION VIDEO