In SMT Manufacturing, quality is not a one-time action but a continuous process of inspection, testing, and validation. At Trungnam EMS (TNEMS) – a leading Electronics Manufacturing Services (EMS) provider in Vietnam, we apply strict multi-step quality assurance to deliver reliable and consistent products to our customers.

Why Quality Control Matters in SMT Manufacturing

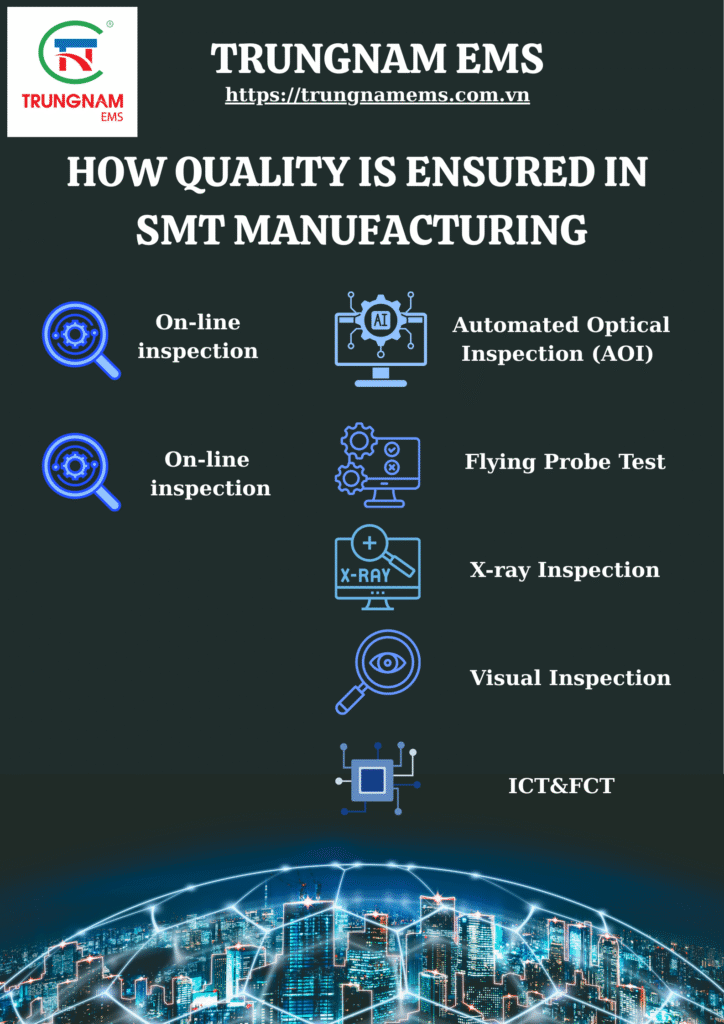

To ensure every PCBA (Printed Circuit Board Assembly) meets international standards, TNEMS implements a combination of online and offline testing methods:

1. Online Inspection

- In SMT manufacturing, online inspection is the first and most critical stage to ensure product quality. At Trungnam EMS (TNEMS), we utilize Automated Optical Inspection (AOI) to detect surface defects, missing components, or soldering issues in real-time during production. Early detection of potential issues not only reduces rework costs but also prevents defective products from moving further down the production line, minimizing the impact on the entire process.

2. Offline Testing

- Flying Probe Test: Validates the electrical performance of PCBA.

- X-ray Inspection: Identifies hidden soldering defects.

- Visual Inspection: Manual examination to detect visible defects.

- ICT (In-Circuit Test), FCT (Functional Test): Verifies full functionality.

By applying these multi-stage quality checks, TNEMS ensures:

- High product reliability for global clients.

- Consistency across large-scale production.

- Customer satisfaction through defect-free deliveries.

Partner with TNEMS for Reliable SMT Manufacturing in Vietnam

With a strong commitment to quality control, TNEMS is your trusted partner for PCBA, SMT, THT assembly, and box-build services in Vietnam.