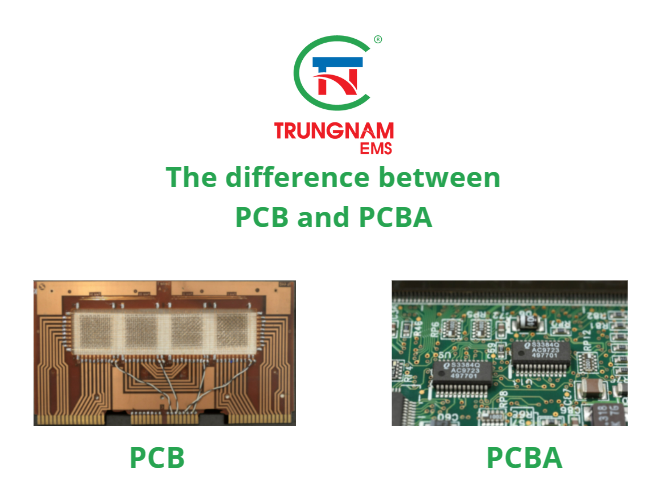

PCB, PCBA and the difference

PCB stands for Printed Circuit Board, which is a sort of electronic board used in the electronics industry. It is created utilizing electronic printing technology, therefore the name “printed” circuit board. PCB is a significant electronic component in the industry since it supports electronic components and serves as a carrier for electrical connections. PCBs are widely utilized in the creation of electronic devices due to their unique properties like as high wire density, compact size, light weight, and automation.

PCBA, or “printed circuit board assembly,” refers to the full process of attaching electrical parts to a PCB. Surface Mount Technology (SMT) and Through-Hole Technology (DIP) are involved in this; where SMT does not call for drilling holes in the PCB, DIP calls for inserting components into pre-drilled holes. Small-sized component manufacture using SMT comprises placing the PCB, printing solder paste, mounting the SMT, reflow soldering, and inspection. The production method for DIP, on the other hand, uses bigger components and includes back glue pasting, component insertion, inspection, wave soldering, board brushing, and inspection.

In conclusion, PCB refers to the bare board

without any components, while PCBA refers to the end product once all the

operations on the PCB are finished. In other words, PCB is a board that hasn’t

been finished, whereas PCBA is a finished product.

Trung Nam EMS hope now it is very much clear about the difference between a PCB and a PCBA.