Importance of Multilayer Printed Circuit Boards

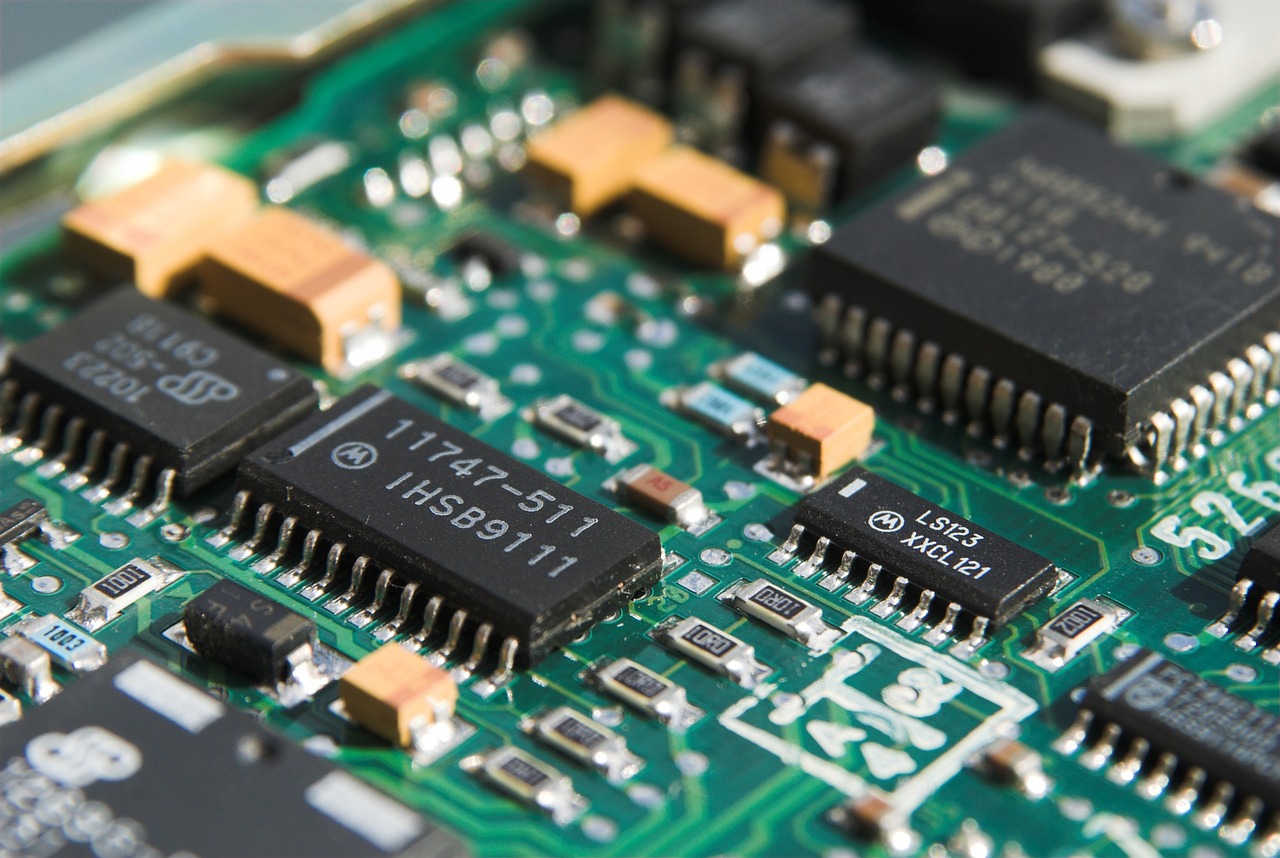

Printed Circuit Boards (PCBs) have become an indispensable component in many of the devices we use in our daily lives. They are present in everything from handheld electronic devices to industrial machinery, communication devices, and consumer electronics. Modern PCBs come in various complex shapes and are made from different materials. They can be flexible or rigid and incorporate a wide array of components interconnected to fulfill specific functions. This level of complexity is achievable primarily with multilayer PCBs.

In the past, PCBs were mostly single or double-layered, serving basic computational or automation purposes. However, contemporary PCBs, particularly multilayer and flexible PCBs, are now commonplace in motherboards, smartphones, smartwatches, biomedical instruments, cryptocurrency mining devices, artificial intelligence-based robotic circuits, and more. Furthermore, advancements in manufacturing techniques have led to faster production, reduced production costs, and smaller PCB sizes.

A multilayer PCB consists of multiple layers of copper that are laminated together, with electronic components soldered on both the top and bottom sides. The inner layers function as double-sided circuits, interconnected to form a thick PCB with multiple layers. Copper tracks, vias, and pads/holes facilitate the electrical connections between electronic components. Vias come in different types, including PTH (plated through-hole), blind, and buried vias. The result is a complex PCB with maximum circuitry in a compact size.

The need for multilayer PCBs has arisen due to the evolution of complex processing and technology. Issues such as noise and stray capacitance, which were prevalent in single or double-sided PCBs, prompted the development of multilayer PCBs.

Multilayer PCBs are available in various layer configurations, typically ranging from 4 layers to 12 layers, depending on the specific application and requirements. Multilayer PCBs are more expensive to produce compared to single-sided PCBs due to the additional steps involved in fabrication. However, their applications are extensive, with smartphones featuring PCBs with up to 8 layers and military electrical equipment potentially employing PCBs with up to 100 layers, though such high-layer PCBs are rare and costly.

Advantages of Multilayer PCBs:

- Miniature Size: Multilayer PCBs are significantly smaller and more compact due to the stacking of multiple layers, connected by vias. This reduction in size is ideal for mobile phones, laptops, and wearable electronics.

- Less Weight: The smaller size of multilayer PCBs results in lighter-weight components, making them easily portable and suitable for handheld electronics.

- High Quality: Multilayer PCBs undergo meticulous fabrication processes, ensuring high quality and reliability compared to single or double-layer PCBs.

- Durability: The manufacturing process subjects multilayer PCBs to high pressures, temperatures, and bonding agents, resulting in strong and durable PCBs.

- More Density: Multilayer PCBs accommodate a higher density of components per unit size, enabling more powerful and efficient electronics.

- More Functionality: The increased circuitry within multilayer PCBs allows for enhanced functionality, making them essential in high-computation electronics like quantum computing, artificial intelligence, cryptocurrency mining, and supercomputers.

- Ease of Installation: Multilayer PCBs simplify installation by integrating multiple functions onto a single board, reducing the need for complex wiring and connectors.

Disadvantages of Multilayer PCBs:

- Costly: Multilayer PCBs are expensive to manufacture due to their complexity, labor-intensive processes, and the need for costly machinery.

- Complex Inspection: Ensuring the quality of multilayer PCBs requires careful manual and automated inspection due to the potential for design flaws.

- Limited Manufacturers: Not all PCB manufacturers can produce multilayer PCBs due to the high equipment and labor costs involved. This limits the availability of quality multilayer PCBs.

- Professional Design Required: Designing multilayer PCBs necessitates the expertise of a professional engineer, as errors can lead to issues like circuit noise, stray capacitance, impedance mismatch, and more.

- Longer Manufacturing Time: The complexity of manufacturing multilayer PCBs results in longer production times, potentially causing delays.

Multilayer PCBs vs. Single Layer PCBs:

Multilayer PCBs are more compact and dense, accommodating more components in a smaller space. They are lighter in weight, suitable for portable devices, and offer enhanced functionality. Single layer PCBs are bulkier and used in larger electronic equipment where size is not a critical factor.

Choosing between single-sided and multilayer PCBs depends on the specific application’s requirements.

Applications of Multilayer PCBs:

Multilayer PCBs find applications in various industries, including:

- Consumer Electronics: Used in smartphones, smartwatches, calculators, remote controls, MP3 players, kitchen appliances, and more.

- Computers and Devices: Commonly found in motherboards, graphics cards, power supplies, keyboards, mice, and other computer components.

- Telecommunication Electronics: Utilized in GPS devices, satellites, communication towers, radar electronics, and more.

- Industrial Automation: Used in robotics, automated assembly lines, car manufacturing, and other industrial applications.

- Medical Devices: Integrated into portable medical equipment like ECG/EEG machines, blood pressure monitors, and diagnostic devices.

- Military, Aerospace, and Defense: Employed in unmanned vehicles, radar systems, satellite control, avionics, and more.

In conclusion, the demand for multilayer PCBs continues to grow, driven by the evolving needs of modern technology across various industries. While these PCBs are more expensive to produce and require professional expertise, they offer compact size, enhanced functionality, durability, and reliability, making them essential components in today’s advanced electronic devices and systems.