First of all, Trung Nam EMS provides a complete solution for all of your electronic manufacturing service requests, from fast turnaround prototyping to high volume manufacture. We can detect design and/or production issues during the prototype stage and resolve them (in collaboration with you) before proceeding to PCB assembly progress

In addition, our turnkey or contracted printed circuit board assembly service is ISO 14001:2015 and 9001:2015 certified. We conduct constructive SMD, through-hole, and mixed assembly projects, and we also provide free DFM inspections and function testing based on your individual needs. Plus, there is no minimum cost criteria and reordering never incurs additional tooling costs.

The Table of PCB Assembly Capabilities:

| No. | Item | Process Capabilities Parameter |

|---|---|---|

| 1 | Order Quantity | ≥1PC |

| 2 | Lead Time | 24 hours expedited service can be offered. 3- 4 days normally for PCBA prototype orders. We will give you an accurate lead time when we quote for you. |

| 3 | Size | 50*50mm~510*460mm |

| 4 | Board Type | Rigid PCB, Flexible PCB, metal core PCB |

| 5 | Min Package | 01005 (0.4mm*0.2mm) |

| 6 | Max Package | No limit |

| 7 | Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

| 8 | Surface Finish | Lead/Lead-free HASL, Immersion gold,OPS etc. |

| 9 | Assembly Types | Surface mount (SMT), Through-hole (DIP), Mixed technology (SMT & Thru-hole) |

| 10 | BGA Package | BGA Dia. 0.14mm, BGA 0.2mm pitch |

| 11 | SMT Parts Presentation | Cut Tape, Partial reel, Reel,Tube, Tray, Laser-cut Stainless Steel |

| 12 | Cable Assembly | We manufacture specialized cables, cable assemblies, wiring looms/harnesses, and power leads for a variety of industries, including automotive, security, mining, medical, and entertainment. |

| 13 | Quality Inspection | Visual inspection; BGA placement – X-RAY checking; AOI checking. |

| 14 | SMT Capacity | 3 Million~4 Million Soldering Pad/day |

| 15 | DIP Capacity | 100 Thousand Pins/day |

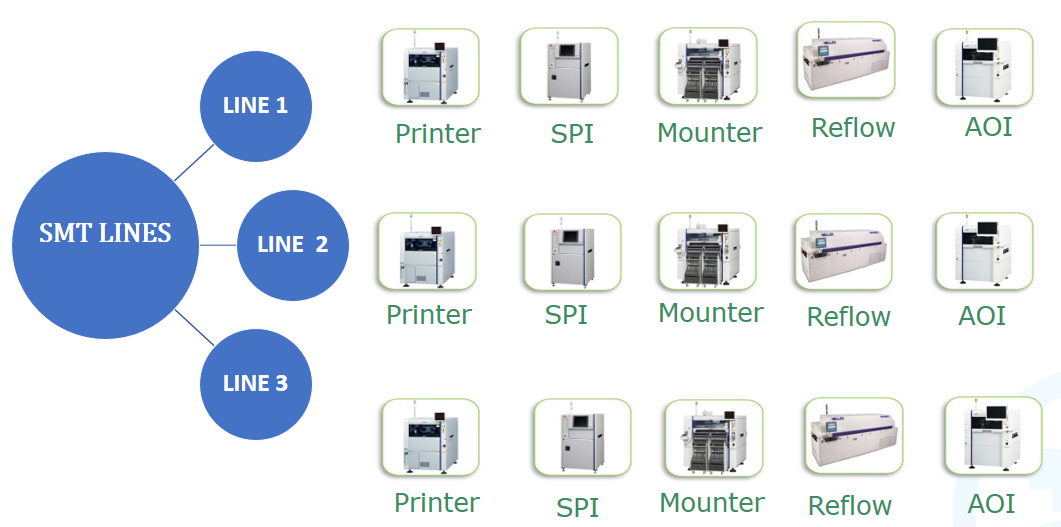

PCB production system: (PCBA)

We will manually handle and visually inspect only the smallest volume of PCBA projects, while the dependable automated gear will process with vast majority of larger projects.

Trung Nam EMS will employ automated technology to solder components on PCB as quickly as possible, using your pick and place CAD data. Normally, Automatic Optical Inspection helps us to verify component locations, orientation, and solder quality. When it comes to hunting for flaws in PCBs, AOI technology has shown to be quite dependable.

Following assembly, TNEMS will send the PCBA images to you for the component positions confirmation. The sooner you reply to the service email, the sooner we can process your order and complete it on schedule.

Contact us or connect with us on Linkedin