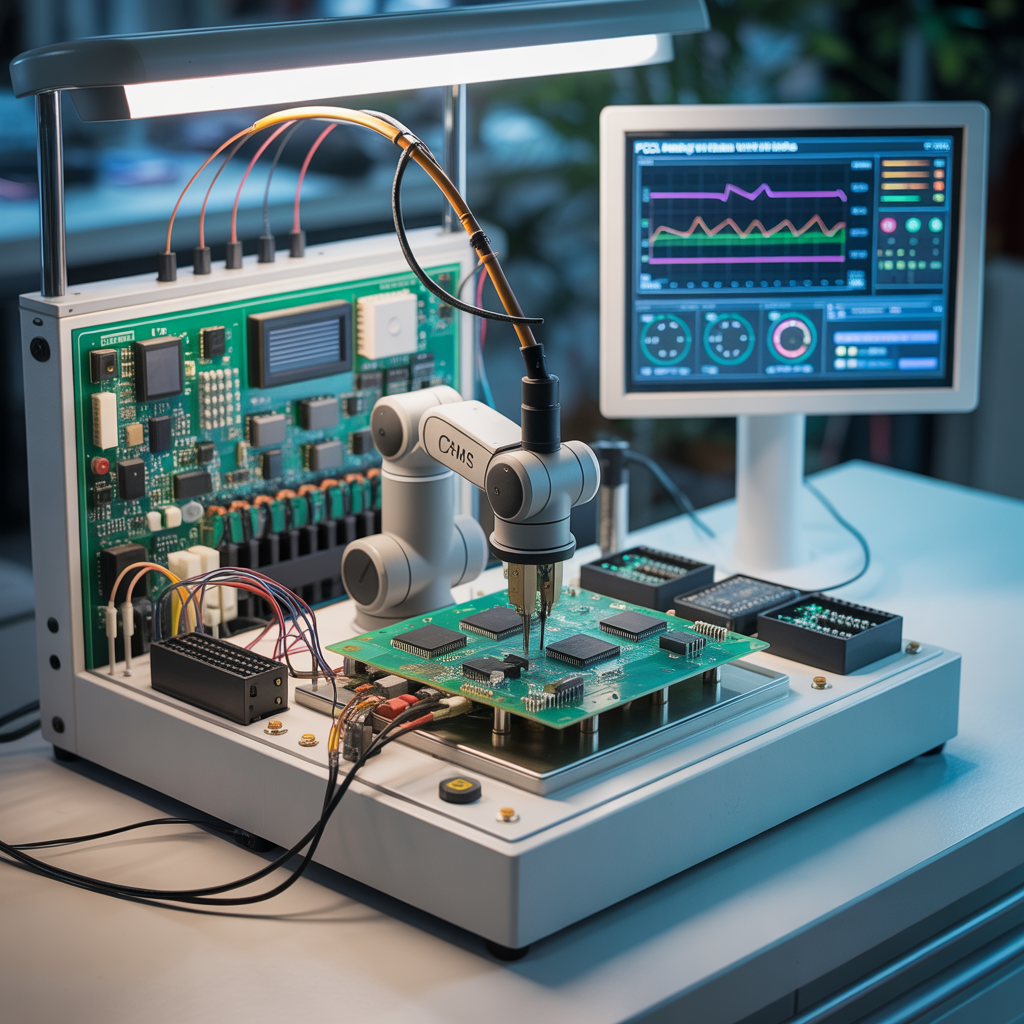

Electronics manufacturing industry – Product Quality and Reliability are non-negotiable. Even a minor defect in Printed Circuit Board Assemblies (PCBA) can cause product failures, costly recalls, and damage to brand reputation. TNEMS – a leading EMS provider in Vietnam, we prioritize quality by investing in state-of-the-art PCBA testing technologies to guarantee that every product we deliver meets global standards.

PCBA Testing Technologies for Comprehensive Quality Assurance at TNEMS

In the field of electronics manufacturing, ensuring product quality is always the top priority. Modern PCBA Testing technologies not only help detect assembly defects but also enhance the overall reliability and performance of printed circuit boards (PCBs). Below are the most widely used and essential PCBA Testing methods:

1. Automated Optical Inspection (AOI)

AOI uses high-resolution cameras to inspect solder joints, missing parts, and misaligned components. This step ensures accuracy during assembly and prevents faulty boards from moving forward.

2. Solder Paste Inspection (SPI)

SPI measures the volume and placement of solder paste during SMT assembly. By catching inconsistencies early, manufacturers can reduce defects and improve production efficiency.

3. In-Circuit Testing (ICT)

ICT evaluates electrical parameters such as resistance, capacitance, and connectivity at the component level. It helps uncover faults early in the process and ensures compliance with design requirements.

4. Functional Circuit Testing (FCT)

FCT validates the overall functionality of the assembled board under real-world conditions, confirming that the final product performs as intended.

5. Burn-In Testing

This method subjects boards to thermal and electrical stress to expose early failures. It improves long-term durability and product reliability.

6. Flying Probe Testing

A flexible solution without the need for test fixtures, flying probe testing is ideal for prototypes and low-volume runs. It checks for opens, shorts, and verifies component accuracy.

7. Automated X-Ray Inspection (AXI)

AXI is especially useful for dense boards and advanced packages like BGAs. It detects hidden soldering defects, including voids and bridges, that are invisible to the human eye.

Why Choose TNEMS for Your PCBA Testing Needs?

Moreover, TNEMS goes beyond standard testing approaches by developing customized testing solutions tailored to your product’s unique requirements. This bespoke attention ensures every PCB assembly is authentic, precise, and reliable for long-term use.

As a trusted partner in Vietnam’s EMS industry, TNEMS combines:

– Cutting-edge PCBA testing technology

– Modern, highly automated SMT assembly lines

– Rigorous quality management systems

So that we deliver electronics products that consistently meet global market demands.

Contact TNEMS Today for PCBA Testing Solutions

If you are searching for a reliable EMS provider in Vietnam offering comprehensive PCBA testing services, look no further.

👉 Contact TNEMS today and let us support your next electronics manufacturing project with confidence and excellence.